Atomized Aluminium Powder

Aluminium Products

Need help?

Silvassa, Dadra & Nagar Haveli – 396 230, INDIA

Email: info@shivamproteco.com

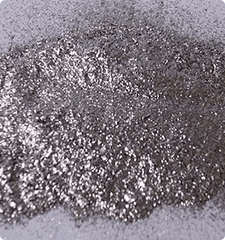

Atomized Aluminium Powder

The conversion of aluminium ingots by melting and atomizing them into fine powder/dust, granules/particles is known as Atomized Aluminium Powder.

Applications

- Ferro Alloys

- Refractory for steel and cement plants.

- Termite Welding (Joint welding for railway tracks)

- Ordnance

- Rocket Fuel

Manufacturing Process

Aluminium Ingots are charged into the furnance and the molten metal is atomized by high-power air jets through a specially designed atomizer and converted into metal powder.

Shivam Proteco Pvt. Ltd. is offering Atomized Aluminium Powder.

Aluminium powder is an essential component in several industries and particularly in the autoclaved aerated concrete (AAC) blocks, lightweight concrete, and construction materials manufacturers. We, at Shivam Proteco Pvt. Ltd., are pioneering manufacturers of high-quality atomized aluminium powder, highly AAC grade powder dedicated to improving the performance and durability of AAC blocks. Our high-grade powder is engineered to provide optimum aeration, strength, and stability, making it an ultimate reference for AAC block manufacturers as well as construction projects.

What is Atomized Aluminium Powder?

The special atomization technique for the production of atomized aluminium powder is when molten aluminium is projected into a chamber and rapidly solidified into very fine spherical particles. It results in specific size, high purity, and excellent reactivity, rendering it an ideal ingredient for AAC blocks and other industrial purposes.

Why Use AAC Grade Aluminium Powder?

AAC grade aluminium powder for use will have specifically formulated characteristics that will help in the efficient reaction with lime and cement for the production of AAC blocks, thus evolving the hydrogen gas that once evolved will create minute air bubbles in the blocks. These air bubbles, in turn, provide the characteristic lightweightness along with high thermal insulation properties to these blocks.

The Advantages of Using Our AAC Grade Aluminium Powder:

Excellent Aeration – Uniform pore structure in AAC blocks gives it strength and durability.

Pure – Being subjected to very strict quality control, be it in chemical composition or performance, but ensures that manufacture is consonantly able.

Lightweight Concrete Invention – AAC Blocks become lightweight, strong, and energy-saving.

High Thermal Insulation – Creates an energy-efficient structure through low heating and cooling costs.

Eco-Friendly & Sustainable – Lowers the carbon footprint of construction by ensuring lightweight recycled materials.

Uses of Atomized Aluminium Powder

Our AAC-grade aluminium powder has the following major uses:

Manufacturing of AAC Blocks – For the controlled aeration process in the manufacturing of autoclaved aerated concrete blocks.

Lightweight Concretes – Workability enhancers, shrinkage reductions of concrete structures.

Paints and Coatings – As a pigment, for corrosion-resistant coatings.

Explosives and Fireworks – Due to their high reactivity and energy released.

Metallurgical Uses – As a reducing agent in various metal refining processes.

Why Choose Shivam Proteco Pvt Ltd?

Shivam Proteco Pvt Ltd is a most trusted manufacturer of aluminium powder whose products meet all industrial standards known. The combination of a manufacturing facility of modern standards, amendment of strict quality control, and continued R&D gives us the edge to carry out superior aluminium powder for AAC block manufacturers and other industrial applications.

Quality Assurance:

Most advanced technology for manufacturing for a very controlled particle size distribution.

Stringent quality control processes for the assurance of purity and performance.

Made-to-order solutions for the individual needs of an industry.

Timely delivery, backed by an efficient customer service team.

How To Get In Touch

Need ultra-high-quality AAC-grade aluminium powder for your company? Switch to Shivam Proteco Pvt. Ltd. for quality and reliability like never before. Do contact us today for any inquiry, bulk supply, or dealership opportunities.